If you’re diving into the world of 3D printing, or even if you’ve had a printer for a while, one truth remains constant: you can’t print without the right material. Simply put, the choice of filament can make or break your project. That’s why we’re talking about why you need 3D filaments, and focusing on three key reasons that go beyond the obvious. And if you’re considering a trusted brand, check out FilaLab for quality sites you’ll appreciate.

3D Filaments Expand Creative Possibilities

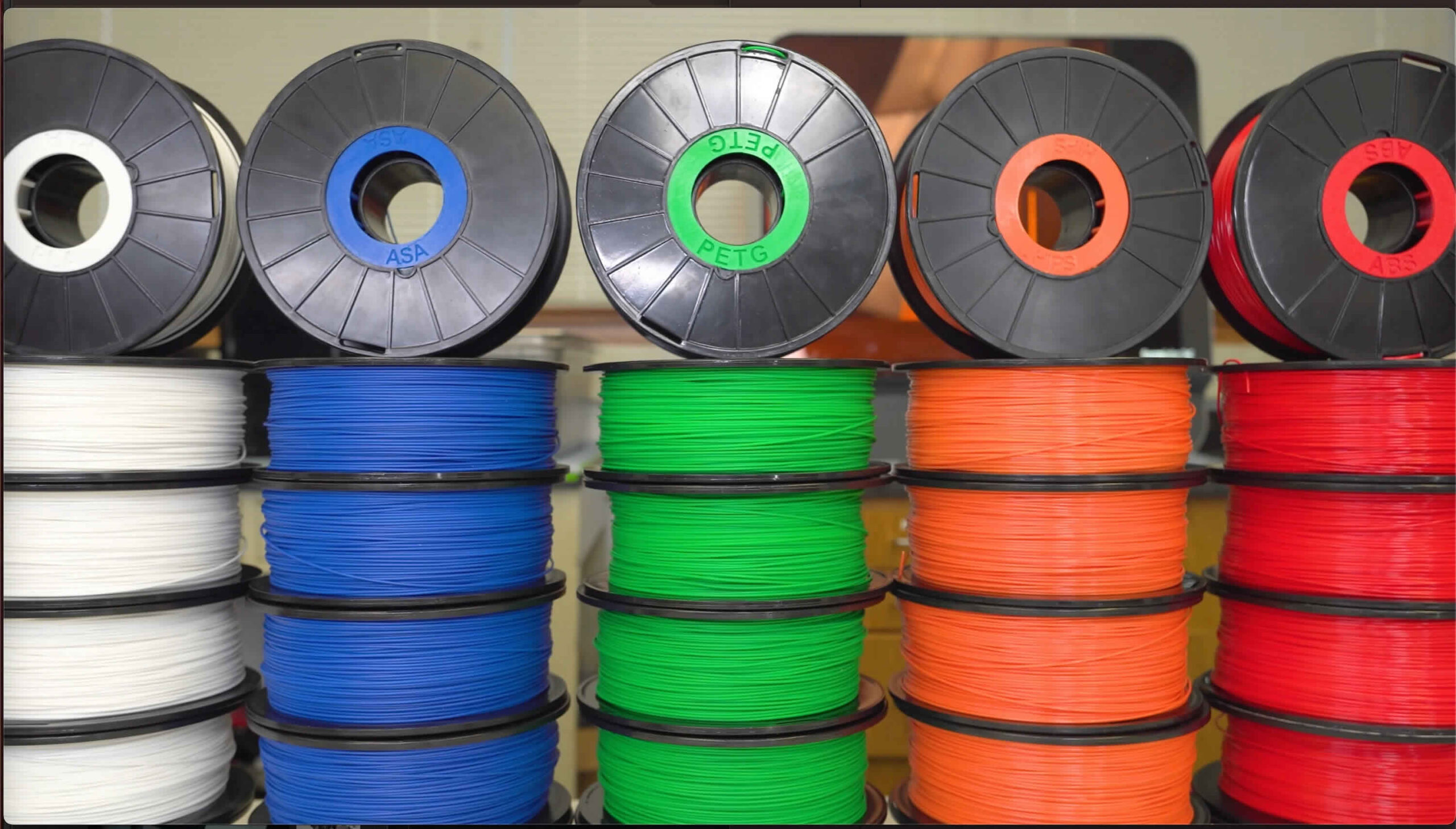

It’s not just about feeding your printer a plastic spool and expecting greatness. Different filament types unlock entirely different creative paths. For example:

- PLA (Polylactic Acid) is great for beginners, easy to print, low-warp, and available in tons of colours.

- PETG offers more strength and durability, making it ideal for functional parts.

- ABS gives you stronger, more heat-resistant results (though you need good ventilation).

- Specialty filaments like TPU (flexible), wood-filled or carbon fibre-filled let you push into decorative or advanced functional territory.

When you realise how many choices there are, you’ll see why you need 3D filaments: they’re the key to turning an idea into exactly the thing you envisioned. With a trusted brand like FilaLab you get consistency and variety, two traits essential when you’re experimenting and iterating.

Moreover, it’s about what you print, figurines, architectural models, mechanical parts, tool holders, each demands a different material. A flexible filament for a phone case, a rigid one for a motor mount, a wood-look for a prop: when you understand that, you’re not just printing, you’re designing smartly.

Better Filaments = Better Printing Results

Here’s a pro tip: your print’s success often hinges not on your slicer settings, but on your material. That may sound harsh, but it’s true. Quality filaments lead to better layer adhesion, fewer clogs or jams, more consistent extrusion, and fewer failed prints. Put another way: you need 3D filaments that perform, otherwise you waste time, filament, and frustration.

With a brand like FilaLab backing you, you’re more likely to get spool after spool that prints similarly, so you stop guessing whether the failure was your settings or the material. You’ll see cleaner surfaces, reliable bridging, fewer stringing issues, and a correspondingly smoother workflow.

And smoother workflow means less stress. Imagine not having to redo a failed print because the filament unexpectedly warped or the colour shifted. Reliable material frees you to focus on creation instead of troubleshooting.

Filaments Let You Tailor Performance to the Purpose

Not all prints are created equal, and neither are their demands. That’s where the real strategic value of having the right filament becomes apparent. You might ask: why do you need 3D filaments? Because they let you match the material to the purpose.

- For a prototype that doesn’t move: PLA might suffice.

- For a moving hinge on a robot arm: go tougher, PETG or ABS or even Nylon.

- For a wearable or a bounce-back part: TPU, flexible filament.

- For an outdoor piece or one exposed to heat: a high-temp filament, maybe ASA or PC.

By choosing consciously, you save yourself from under-performing parts or prints that fail when pushed. Using FilaLab’s well-specified material means you know exactly what you’re getting, so your part behaves the way you need it to in its real-world context.